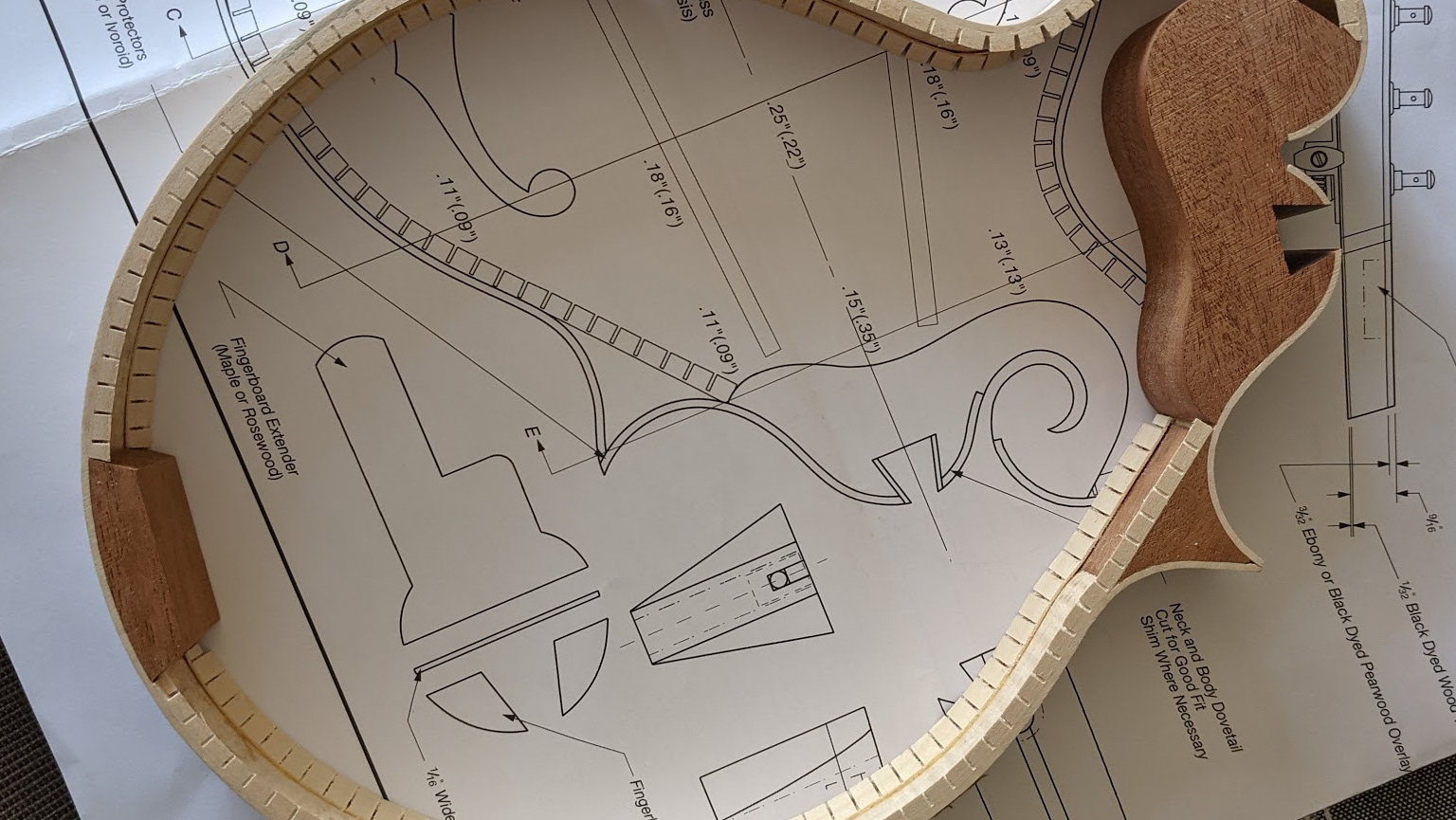

Day 1: Mentally prepared with the knowledge that this will be a journey, and with zero plans for the next two days I set out to start binding the mandolin body.

I drilled multiple holes in the beam I used for gluing the back so I could run spool clamps through it and give myself a solid platform for working the binding with easy access to run rubber bands around the body.

I started with the front, I probably should have started with the back as the front is more visible and I have never bound anything before.

It was super fiddly and took ~6hours but I managed to get the entire front part bound. This came out far from perfect, some gaps, some sloppy miters, but I didn’t have any major disasters, and for the most part it looks alright. I am pretty darn happy with alright as I am new to binding, and I hear F mandolins are pretty tough.

The hardest part was getting the right heat on the binding, not so much it melted, not so little it delaminated and wrinkled when bending. Also, next time I make a strip of binding I will use A LOT more acetone, there were several gaps I had to on-the-fly re-laminate while doing this.

Day 2: Using the lessons learned from the previous day I set out to do the back. It went much faster, and the result was much cleaner. Almost burned my fingers off with the heat gun when shaping the little button piece. Feels good to have this part done, imperfections aside. I have tremendous respect for the skill of professional luthiers, watching pros do binding makes it look so easy, this was for sure a challenge.

After this was done, I sanded the top side flush, really satisfying to see that part finished, and super happy with the results now that it is cleaned up. I am still waiting for the back to fully cure, so I will save sanding that one flush for tomorrow.

Lessons learned from the binding process

Routing

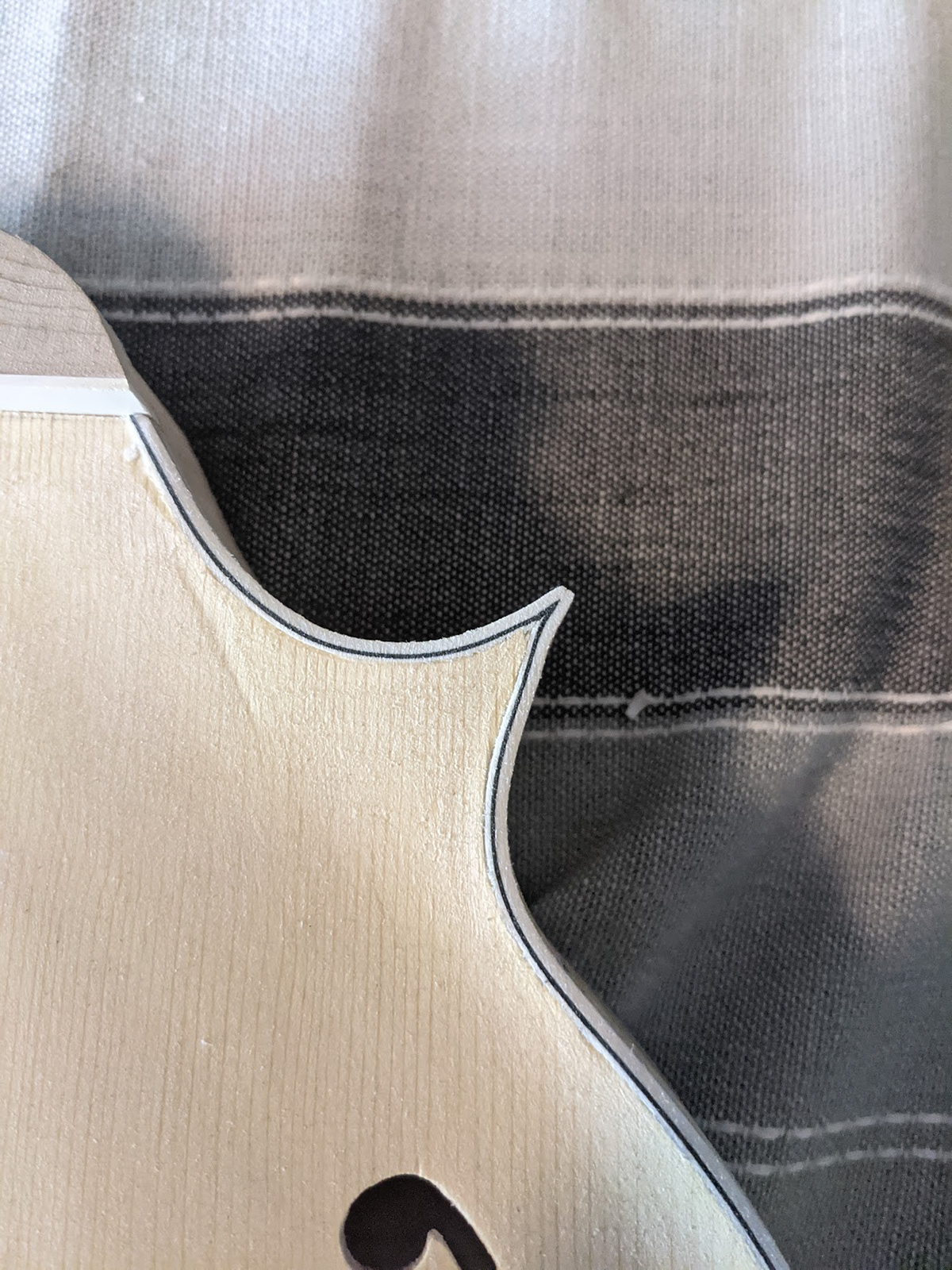

- One spot where the jig slipped (bolt not tight enough) and the channel was a bit too deep

- One spot where the Dremel bucked and had some tear out

- One spot where I lost track of grain and had some tear out

- Tough to get the channel just right in the scroll hand routing, made my scroll point too pointy, hard to get binding that sharp.

Binding Lamination

- Couple spots where it wasn't properly laminated leading to wonkiness when bending

Binding Bending

- Couple spots with the wrong heat when bending the binding in a tight loop, lead to some wrinkles on the inside

- Mitering is just hard to get right

- In general this is an art and takes practice. I think if I had triple the binding material and I wanted it to be perfect I could get there, but it is hard and I am okay with some mistakes. I am trying not to stall out completely due to perfectionism, I want a complete mando, not a perfect one.

Gluing

- Couple spots that weren't properly pressed in super well with the rubber bands that I missed when inspecting while curing, should be able to fix these with some heat.